Description

Types

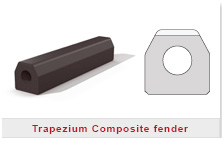

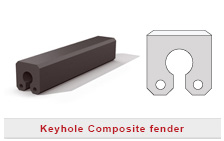

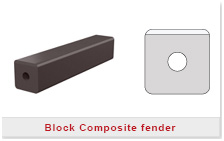

Engineer Company produces a standard range of composite fenders in block, keyhole and trapezoidal form:

• Block composite fender

• Keyhole composite fender

• Trapezium composite fender

The most common dimensions are kept in stock and can therefore be delivered at short notice. Non-standard sizes and customer specific versions can also be produced and delivered with short lead times.

Processing

Composite fenders are normally mounted between two strips or in a U-beam. The required mounting holes are made through the side of the fender. Composite fenders can be supplied in any desired length and the ends can be bevelled.

Applications

Composite fenders are widely used in various sizes and designs on:

- workboats

- barges

- tugboats

- pontoons

- water locks

- ports

- quays

- piers