Description

Introduction :

Cargo storage spaces of any type of vessel, need to be well protected in order to preserve the cargo and prevent any kind of spoilage. A cargo space needs to be air and water tight for conserving the cargo goods for a longer time. If the cargo that is food items, then it becomes extremely important to protect it from moisture and adverse weather conditions, especially rain. Inability to do this not only results in spoilage of goods but also produces chances for spreading diseases. Hatch covers come to the rescue in this situation and can be compared to the lid on a box.

Hatch Covers

In a hatch cover system, the following three safety barriers will be required:

- A strong steel structure

- Packing rubber (flexible seal with design compression to compensate for known movements)

- Designed to be compressed to a certain depth, which is generally referred to as the design compression

Hatch cover rubber packing

Many different types of hatch cover rubber packing (also referred to hatch cover rubber sealing). Traditionally sponge rubber packing was used pressing it against the edge of a compression bar. Over the years ships became much larger and so having bigger movement between the coaming and the hatch covers. To solve this issue sliding rubber packing was used

Hatch cover rubber packing supplied by Engineer Company is made of high quality material to guarantee a long life time. Our sliding rubber offers low friction for better sliding together with a minimum wear. Furthermore it is UV radiation resistant and applicable in a big temperature range. Our sponge rubber has a strong solid skin to reduce damage on the packing. The sponge core is fabricated from a strong natural rubber offering the best compression and a minimum wear.

Sponge rubber

- Mostly used on side rolling and folding hatch covers

- Consists of a solid skin with a sponge rubber core

- Standard compression: 12mm

- Produced to guarantee long life time

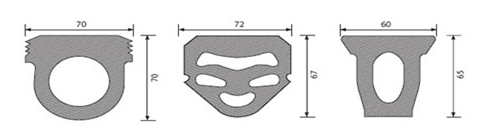

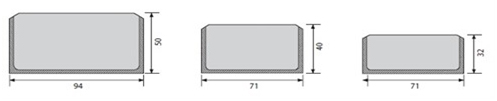

Our main types of Sponge Rubber Packing :

Sliding rubber

- Mostly used on large vessels with folding hatch covers

- Consists of EPMD material

- Standard compression: 12mm

- Produced to guarantee long life time

Our main types of Sliding Rubber Packing